After more than two decades in the industry, Rodney Davenport was given the opportunity to create an injection molding operation in his own vision, and — in keeping with the product he was making — to do so from the ground up. #planttour

In August 2015, Rodney Davenport helped establish in-house molding for the Recreational Group in Dalton, Ga. Photo Credit: Plastics Technology Plastic Packing Mould

Rodney Davenport’s professional and adult life has been in injection molding. Starting in 1993 right out of high school, he spent a decade at custom molder Clairson Industries in Florida, wearing every hat a worker can and working alongside his mentor, Archie Mann. After some ownership changes, he eventually found his way to Georgia and was running operations at ADCO Plastics in Marietta, when a floor tile mold ended up in his shop after posing problems for the last company that ran it. ADCO got the mold back into successful production, and Davenport found himself in conversation with the owner of the floor tile company, The Recreational Group (RG).

“He brought sheets of tiles and said, ‘Tell me what’s wrong with these,’ and I told him, and he said, ‘Well this is not what the other molder is telling me,’ and I was like, ‘Well, we’re transparent; we’re going to tell you what’s going on — good or bad or whatever.’” That evening, Davenport got a LinkedIn message from the owner: “Call me tomorrow.”

RG’s owner was as direct on the phone as he’d been over LinkedIn. “He says, ‘I’m tired of dealing with everybody outside; we want to mold our own product inside and bring it all in-house; would you be interested in coming and starting a company for me?’’’ With the support of (and a gentle nudge from) his wife, Davenport told RG he was in and CH3 Solutions, Dalton, Ga., was born. He started with the company in April 2015; equipment was ordered by June and the first tiles molded on August 3, running from two machines.

Fast-forward to April 2022, and CH3 Solutions is completing a move into a new 200,000-ft2 facility that will house it and its RG sister companies. The company now has six injection molding machines, ranging from 730 to 1500 tons. Apart from a 1997 Engel, all the machines are from Engel’s Wintec brand of economical two-platen presses. Davenport initially scoped out the Wintec machine during its U.S. debut at the NPE2018 trade show, and CH3 soon became the company’s first U.S. customer. The press bought that day is at the front of the line on the company’s molding floor, and it has been running nonstop since installation, molding tiles for for basketball and tennis courts.

Dubbed the Carpet Capital of America — or the World, depending on who you ask — Dalton has been a hub for flooring production as far back as the 1890s when the tufted bedspread industry that precipitated modern carpeting was born here and Bedspread Alley sprouted up along U.S. Highway 41. Today the factories of flooring giants like Mohawk and Shaw surround Interstate 75, and alternative flooring producers like RG also call the area home. RG’s brands include XGrass, Versacourt, Tour Greens, Swisstrax, and Landmark Designs and encompass everything from interlocking garage-floor tiles and synthetic turf to playground surfacing and inline-hockey flooring.

The tiles CH3 molds range in size from 10 x 10 in. up to 30 x 30 in. and are available in 22 different colors. (Photo: Plastics Technology)

CH3 molds proprietary products for RG, including tiles for athletic courts and some specific products for garages. The tiles range in size from 10 x 10 in. to 30 x 30 in., and all are molded from PP, in some cases talc-filled. Processing 6 million lb of resin/yr, with plans to add a resin silo this summer, CH3 moldstiles in 22 different colors, with all colorants blended into natural PP at the press via Maguire loaders and blenders.

Over his three decades of injection molding, Davenport has worked on extremely challenging parts from medical, including implants, to automotive, consumer produces and more. But despite their seeming simplicity, floor tiles have posed the biggest challenge. “It looks super simple, but it’s the hardest molding I’ve ever done,” Davenport says.

From avoiding warpage in parts that must be flat to keeping color completely consistent for larger courts with hundreds of tiles, to nailing precise dimensions every time, the tiles’ biggest challenge is how they’re presented in their end use. “Keeping the warpage out, keeping the size correct, matching everything perfectly,” Davenport says. “It’s not like some things where you might run a bunch of a color, but the parts don’t ever touch each other. These touch each other on four sides.” In addition to “using all the math we can to get all the wall thicknesses correct,” Davenport says CH3 has also figured out process steps and parameters to keep the tiles flat.

When a job is started, a standard tile is pulled from a wall display holding the benchmark products for comparison, with a keen eye on the material. “We really keep our lots close,” Davenport says of the PP used for the tiles. “We try not to mix too many lots to keep the color consistent.”

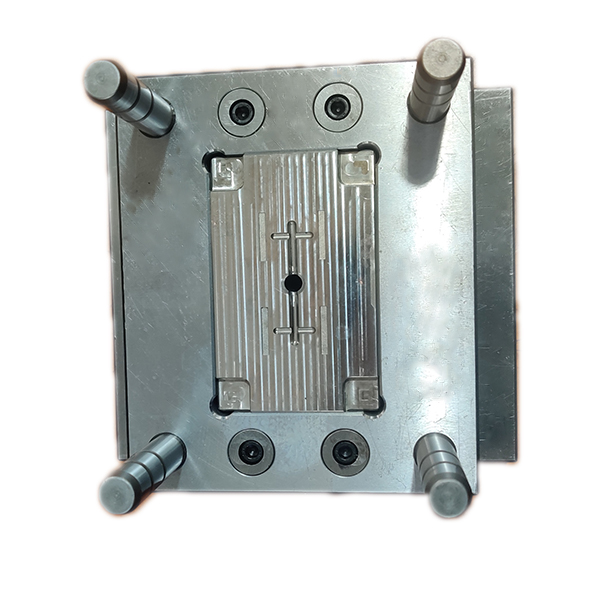

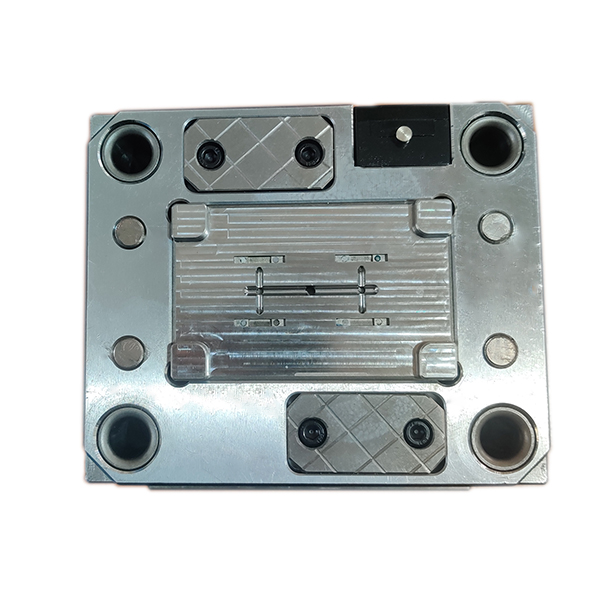

CH3 has 100 active tools, 90 that run continuously producing floor tiles in hot-runner molds with two or four cavities. (Photo: Plastics Technology)

Reflecting on past consumer-products molding, Davenport offers an example of the inherent challenge. “I used to make a lot of stuff for Colgate — deodorant caps and things. If the caps were slightly off it wasn’t that big a deal because you’re seeing just one at a time. Once in a while, if they were all lined up on the shelf, you might see a difference but it had to be pretty drastic. With the tiles, you’ve got parts touching on every side, and then you can look across and if something’s off, you will see it, it will pop out.”

“We listen to our operators a lot because they’re always on the machine, and they’ll say, ‘Hey, this sounds different.’”

Those defects will “pop out” in the same building were they were made since flooring assembly and painting occurs on the opposite end of the facility where CH3 molds the tiles. From backyard basketball and shuffleboard courts to full-sized tennis courts, the bulk of the flooring ordered from RG and molded by CH3 is customized in size, color, decoration, etc.

When Plastics Technology visited, a halfcourt basketball court in light brown was being finalized with the family’s surname and “Est. 2012” painted in the key, while the building’s far corner was occupied by two full-sized tennis courts receiving finishing touches. Here, using the customer’s order as a guide, workers laid down tape on the interconnected tiles prior to painting on lines, markings, logos and more. Once the paint dries, the workers disassemble and number the individual tiles, packing them up into a kit that will be reassembled in sequence using those numbers as a guide.

Given the strict quality requirements of the product being made, a visitor might expect to see a large quality-control department — not here at CH3. QC is handled by operators and supervisors, Davenport says, noting that CH3 requires its workers to wear multiple hats. Case in point: maintenance crews are trained to start up presses.

From his earliest days in molding, Davenport was often puzzled by how injection molders manage quality. “You should know what a good part is,” he says. “It shouldn’t be that you mold a part, hand it to QC and ask, ‘Is this good?’’ CH3 runs lean with four people per shift and, at present, two shifts. Aiding in quality control is a Keyence XM Series portable CMM for 3D and geometric dimensioning and tolerancing (GD&T) measurements. Located among the machines instead of being cordoned off in its own room, the device allows workers to quickly inspect the tiles’ dimensions. Average scrap at CH3 is less than 1%, and most of that comes from color changeovers, with transition parts scrapped as the previous run is purged. That low scrap rate is one reason why CH3 has twice been honored as a Top Shop in Plastics Technology’s Benchmarking survey.

Warpage is the biggest challenge for CH3 solutions to overcome in its floor tile molding, with color matching a close second. (Photo: Plastics Technology)

The desire to establish a molding operation where workers are challenged to think critically and learn is core to Davenport’s bid to buck the shopfloor dynamics that he’s seen over the years. “The industry has grown a lot; it’s changed a lot,” Davenport says. “Machinery has really changed over the years, but the real deep down at every shop is the same. You have one guy who usually fixes everything who ends up being a process engineer. You have one guy that’s been there forever so he has all the tribal knowledge, and he’s the one they get to fix the widget, and those are the types of things that always drove me crazy. I want everybody to know everything.”

“You should know what a good part is,” Davenport says. “It shouldn’t be that you mold a part, hand it to QC and ask, ‘Is this good?’’

In addition to empowering his workers to wear multiple hats and exert autonomy over the shop floor, Davenport encourages them to continuously share the status of the machines they’re using, even if they have bad news. “Almost every shop that I’ve ever worked in has had the same philosophy,” Davenport says: “Keep ‘em running, keep ‘em running. The customer is going to be mad if we shut down. We’ve got to make product.”

Davenport has always contrasted that with what injection molding consultant and trainer (and frequent Plastics Technology contributor) John Bozzelli told him and his classmates in a 1994 seminar: If a mold’s broke, fix it. If a machine’s broke, fix it. In that spirit, Davenport says his operators always have his ear, because he trusts theirs. “We listen to our operators a lot because they’re always on the machine, and they’ll say, ‘Hey, this sounds different.’ So instead of just shrugging that off, let’s look into it and see what they’re talking about.”

Since its first Wintec machine purchase following NPE 2018, CH3 Solutions has added four more in addition to its dynasty Engel press. Photo Credit: Wintec

In addition, Davenport says CH3 vigorously adheres to preventive-maintenance schedules for all its equipment, as dictated by the equipment OEM. “Just like your car — you’ve got to get your oil changes; you’ve got to do your fluid flushes at 30,000 miles, 60,000 miles, whatever. You’re spending millions of dollars on this equipment, why not take care of it?”

To help manage the PM on everything from TCUs and blenders to molding machines and robots, CH3 deploys Progressive Components’ CVe monitor. Originally designed specifically for molds, CH3 has worked with Progressive to extend this online monitoring system to all equipment and to track overall efficiency as well as cycles and PMs.

This August, Davenport will mark his 30th anniversary in injection molding, starting life as a floor person and working every job since then. Today he oversees an operation that reflects what he views as the molding ideal, but he acknowledges the unique opportunity CH3 Solutions presented.

“At the end of the day, we had the advantage,” Davenport says. “CH3 is a brand-new company. We started it, and we built the culture the way we wanted it, so it was a little easier than trying to change everything.”

Prior to shipment and after molding by CH3, all the custom courts created by RG are laid out, taped off and hand painted.

CH3 currently utilizes sweeper unloaders from Maguire to empty the gaylords of PP used to mold its tiles.

RG utilizes all of its 200,000 ft2 in Dalton, Ga., particularly for larger projects like these tennis courts.

Maguire loaders/blenders are utilized to feed virgin resin, reclaimed resin, colorant and Asaclean purging compount during color changes.

No pre-colored resins are used by CH3 solutions, which must ensure consistent color across a given project utilizing color additives..

We at Plastics Technology have been grateful that John has regularly contributed Injection Molding Know How columns to our publication since 2010. In this collection, we present you with five articles that we think you will refer to time and again as you look to solve problems, cut cycle times and improve the quality of the parts you mold.

Formerly a showroom for early-aughts-era Van Dorn hydraulics, the newest additions to Drummond Industries’ transforming fleet are all-electric Niigata injection molding machines.

Do you know how to repair the threaded holes in your injection molding machine? C-Sert Manufacturing shares how easy it can be to make this fix.

Plastic Parts From Injection Mould © 2023 Gardner Business Media, Inc. Privacy Policy [Log On]